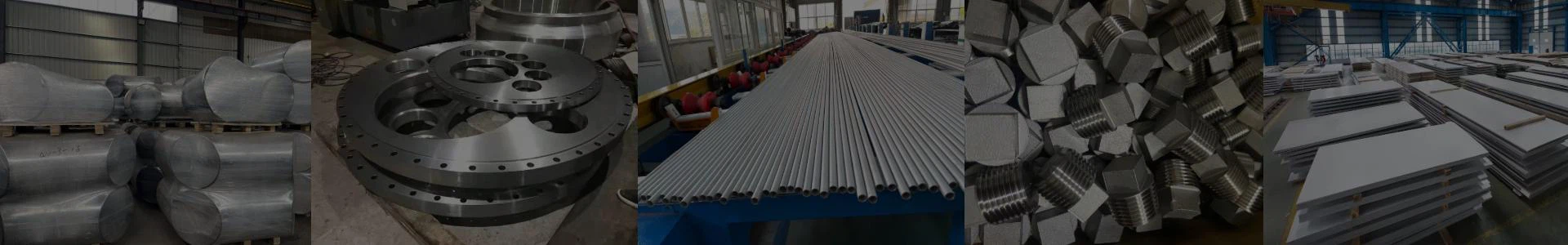

Alloy 718 Ring

SSM supplies Alloy 718 Rings (UNS N07718) conforming to ASTM B637 / AMS 5596, offering exceptional high-temperature strength, corrosion resistance, and fatigue performance for aerospace, power generation, and industrial applications.

Material Overview:

Material Grade: Alloy 718 (Inconel 718)

UNS Number: N07718

Standards: ASTM B637 / AMS 5596

Form: Ring / Forged Ring

Type: Nickel-Chromium-Iron Alloy, Precipitation-Hardened

Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 17–21 |

| Iron (Fe) | ≤ 19 |

| Niobium + Tantalum (Nb+Ta) | 4.75–5.5 |

| Molybdenum (Mo) | 2.8–3.3 |

| Titanium (Ti) | 0.65–1.15 |

| Aluminum (Al) | 0.2–0.8 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

Key Features:

Excellent high-temperature strength and creep resistance up to 700°C (1290°F)

Outstanding corrosion and oxidation resistance

Precipitation-hardened for superior mechanical properties

Good fatigue and stress rupture resistance

Suitable for forging, machining, and welding

Typical Applications:

Aerospace and gas turbine components (discs, shafts, rings)

High-temperature fasteners and flanges

Jet engines and rocket propulsion systems

Nuclear and power generation equipment

Industrial gas turbines and high-performance machinery

Hot Tags: alloy 718 ring, China alloy 718 ring manufacturers, suppliers, factory

You Might Also Like

Send Inquiry