Inconel: Composition, Material Grades, and Products - A Comprehensive Guide by SSM

Inconel is a nickel-chromium-based superalloy known for its high resistance to corrosion, oxidation, and high-temperature environments. It is commonly used in applications such as gas turbines, nuclear reactors, and chemical processing equipment. In this article, we will explore the composition, mechanical qualities, and material grades of Inconel, as well as its available products, specifications, and applications.

Composition and Mechanical Qualities of Inconel

Inconel is a family of nickel-based superalloys that are composed of varying amounts of nickel, chromium, iron, and other elements such as molybdenum, copper, and titanium. The alloy's composition is specifically designed to provide excellent resistance to corrosion and high-temperature environments.

The mechanical qualities of Inconel are dependent on its composition and manufacturing process. Generally, Inconel has a high tensile strength, high yield strength, and good ductility. Its mechanical properties make it ideal for high-stress applications such as jet engine components, pressure vessels, and chemical processing equipment.

The following table shows the composition of some common Inconel alloys and their mechanical properties:

|

Alloy |

Composition |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

Inconel 600 |

Ni 72%, Cr 15.5%, Fe 8%, Cu 0.5%, Mn 1%, Si 0.5% |

690 MPa |

310 MPa |

40% |

HRB 88 |

|

Inconel 625 |

Ni 58%, Cr 20-23%, Mo 8%, Nb+Ta 3.5%, Fe 5% |

827 MPa |

414 MPa |

30% |

HRB 95 |

|

Inconel 718 |

Ni 52.5%, Cr 19%, Fe 18.5%, Mo 3%, Nb+Ta 5%, Al 0.9% |

1,300 MPa |

930 MPa |

30% |

HRB 30 |

Inconel Material Grades

Inconel is available in several material grades, each with unique properties and applications. The following are some common Inconel material grades:

Inconel 600: This is the most commonly used Inconel alloy due to its excellent resistance to corrosion and high-temperature environments. It is commonly used in applications such as heat exchangers, chemical processing equipment, and gas turbine components.

Inconel 625: This alloy has superior corrosion resistance and high-temperature strength compared to Inconel 600. It is commonly used in applications such as aerospace components, chemical processing equipment, and nuclear reactors.

Inconel 718: This is a high-strength alloy that can withstand extreme temperatures and high-stress environments. It is commonly used in applications such as gas turbine components, aerospace components, and nuclear reactors.

Other commonly used Inconel material grades include Inconel 825, Inconel X-750, and Inconel 690.

Inconel Products and Specifications

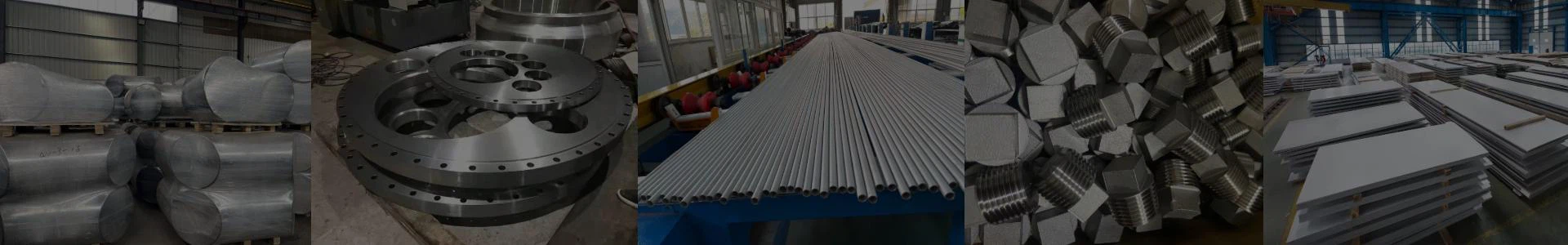

As a leading provider and producer of Inconel products, SSM offers a wide range of Inconel products in various shapes, sizes, and specifications. Some of the most commonly used Inconel products include:

Pipes and Pipe Fittings: Inconel pipes and pipe fittings are widely used in high-temperature environments and corrosive applications. They are available in various sizes, lengths, and thicknesses.

Flanges: Inconel flanges are used to connect pipes, valves, and other equipment in high-temperature and corrosive environments. They are available in various pressure ratings, sizes, and materials.

Plates: Inconel plates are commonly used in chemical processing equipment, heat exchangers, and gas turbines. They are available in various thicknesses, widths, and lengths.

Bars: Inconel bars are used in various applications, including aerospace, chemical processing, and marine engineering. They are available in various diameters and lengths.

SSM offers a wide range of Inconel products with different specifications and grades to meet the specific requirements of different applications. For example, Inconel 600 pipes and pipe fittings are available in various sizes ranging from 1/8" to 12" in diameter, with wall thicknesses ranging from 0.049" to 1.000". Inconel 625 plates are available in thicknesses ranging from 0.1875" to 2.000", with widths up to 48" and lengths up to 120". Inconel 718 bars are available in diameters ranging from 0.25" to 14.00".

In addition to the above products, SSM also offers other frequently used Inconel products such as sheet, wire, forgings, and castings. All of our Inconel products are manufactured using the latest technology and highest quality materials to ensure that they meet the highest industry standards.

Applications and Scope of Inconel

Inconel is used in a wide range of applications that require high strength, corrosion resistance, and high-temperature resistance. Some of the common applications of Inconel include:

Gas turbines: Inconel is commonly used in gas turbine components such as combustion chambers, blades, and exhaust systems due to its high-temperature strength and corrosion resistance.

Aerospace: Inconel is used in aircraft engine components, including turbine blades and discs, due to its excellent high-temperature strength and resistance to fatigue and creep.

Chemical processing: Inconel is used in chemical processing equipment, such as heat exchangers, due to its excellent corrosion resistance in highly corrosive environments.

Nuclear reactors: Inconel is used in nuclear reactor components due to its excellent corrosion resistance in highly corrosive environments and high-temperature strength.

Marine engineering: Inconel is used in marine engineering applications such as seawater corrosion-resistant piping systems and heat exchangers due to its excellent corrosion resistance in seawater environments.

In summary, Inconel is a highly versatile and reliable nickel-based superalloy that offers excellent resistance to corrosion, oxidation, and high-temperature environments. It is available in various material grades and products, making it suitable for a wide range of applications in different industries. As a leading provider and producer of Inconel products, SSM offers high-quality Inconel products with different specifications and grades to meet the specific requirements of different applications.