Inconel 625 Chemical Composition and Physical Properties Explained

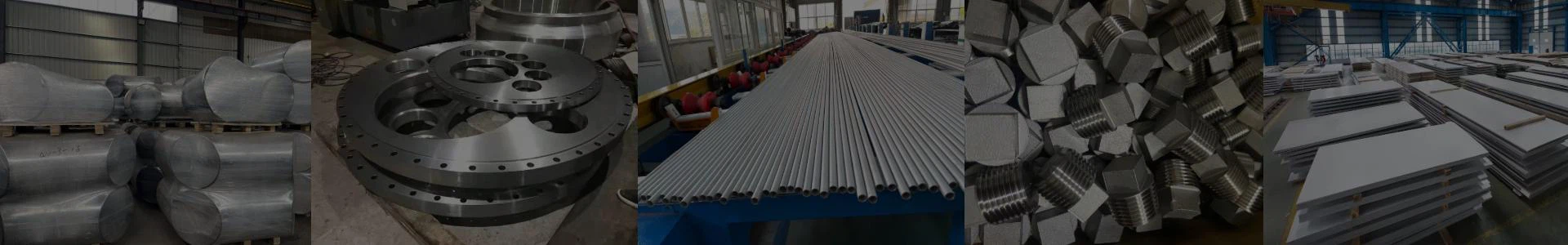

Inconel 625 is a nickel-based superalloy renowned for its exceptional corrosion resistance and high-temperature strength. Widely used in aerospace, chemical processing, and marine engineering, this article provides a detailed overview of Inconel 625's chemical composition, physical properties, mechanical strength, and typical applications to guide your material selection.

1. Chemical Composition of Inconel 625

Inconel 625 is a highly alloyed material. The following table shows its typical chemical composition by weight percentage:

| Element | Content (%) | Function Description |

|---|---|---|

| Nickel (Ni) | ≥58 | Base element; provides corrosion and oxidation resistance |

| Chromium (Cr) | 20.0–23.0 | Enhances oxidation and corrosion resistance |

| Molybdenum (Mo) | 8.0–10.0 | Improves pitting and crevice corrosion resistance |

| Iron (Fe) | ≤5 | Present as an impurity; can aid in machinability |

| Niobium (Nb) + Tantalum (Ta) | 3.15–4.15 | Provides high-temperature strength and creep resistance |

| Manganese (Mn) | ≤0.5 | Enhances hot workability |

| Silicon (Si) | ≤0.5 | Controls impurity content |

| Carbon (C) | ≤0.1 | Reduces the risk of intergranular corrosion |

| Sulfur (S) | ≤0.015 | Controls impurities |

| Phosphorus (P) | ≤0.015 | Lowers the risk of hot cracking during welding |

2. Physical Properties of Inconel 625

The physical properties of Inconel 625 enable it to remain stable under extreme conditions:

| Property | Value |

|---|---|

| Density | 8.44 g/cm³ |

| Melting Range | 1290–1350°C |

| Electrical Conductivity | 1.2 MS/m (at 20°C) |

| Thermal Conductivity | 9.8 W/m·K (at 20°C) |

| Coefficient of Thermal Expansion | 13.0 μm/m·°C |

| Elastic Modulus (Young's) | 207 GPa |

| Magnetic Property | Non-magnetic |

3. Mechanical Properties

Inconel 625 exhibits excellent tensile strength and creep resistance, making it suitable for high-pressure and high-temperature applications:

| Property | Value (at room temperature) |

|---|---|

| Tensile Strength | ≥827 MPa |

| Yield Strength (0.2% offset) | ≥414 MPa |

| Elongation | ≥30% |

| Hardness (Rockwell B) | 92–100 HRB |

| High-temperature Creep Resistance | Stable up to 982°C |

4. Typical Applications

Thanks to its outstanding performance, Inconel 625 is used in a variety of industries:

Aerospace: Exhaust systems, turbine blades, combustion chambers

Chemical Processing: Reactors, heat exchangers, acid-resistant piping

Marine Engineering: Deep-sea components, seawater heat exchangers, platform structures

Nuclear Industry: Reactor parts and components for irradiated environments

5. Why Choose Inconel 625?

✅ Excellent high-temperature oxidation and creep resistance

✅ Superior corrosion resistance in seawater and acidic environments

✅ Good weldability with no need for post-weld heat treatment

✅ Long service life and low maintenance cost