Handling Defects in Bend Pipes and Demagnetizing Bend Pipes

For those who place a high value on the appearance of pipelines, any defects in the pipes are unacceptable. In the process of working with medium-frequency bend pipes, especially on the surface of the pipes, any defects should be promptly addressed. These defects not only affect the aesthetics of the pipeline but can also impact the normal construction of the pipeline. So, how can defects in pipelines be handled?

Check if the molds for medium-frequency bending are smooth and if the temperature is too high.

Reduce the injection speed of bend pipes to eliminate surface defects. In general, the right values to reduce the occurrence of pipe defects can be achieved by lowering injection pressure and flow rate.

If there are surface defects in medium-frequency bend pipes, and stainless steel is used in the pipelines, it may be due to inadequate toughening of the raw material or insufficient forming temperature, making it prone to cold material on the bend pipe surface, resulting in a "butterfly spot" on the bend pipe surface.

Therefore, grinding work on medium-frequency bend pipes should be done meticulously and relevant treatments should be carried out. Inspection work should be performed before pipeline construction, and if necessary, special anti-corrosion tape can be applied to protect against defects.

Bend pipes can come into contact with various materials, and their magnetic properties can affect the performance of the pipeline, potentially undermining its effectiveness. It is essential to demagnetize and eliminate interference to ensure that the pipeline's performance is not affected. So, how can we demagnetize pipelines? First, we need to understand the causes of magnetism, and then proceed with demagnetization.

I. Reasons for the Generation of Magnetism:

Magnetic properties can result from fluctuations in chemical composition or different processing conditions.

After cold working, steel structures may transform into martensite aging, and the greater the degree of cold deformation, the better the magnetic properties of steel.

Welding of magnetic bend pipes often presents issues like difficult arc initiation, unstable arc burning, deviation of the arc within the magnetic field, splattering of liquid metal and slag from the molten pool, etc. To stabilize the welding process and improve the quality of the welded joints, demagnetization of the magnetic pipes should be carried out before welding.

Based on the pre-welding demagnetization, determine the remaining magnetic size and direction of the bend pipes, choose the demagnetization methods, systems, and technical means, demagnetize the bend pipes or welded joints using the selected demagnetization method, and inspect the remaining magnetic quantity after demagnetization.

II. Demagnetization Methods:

Magnetic cleaning, which uses an external magnetic field to process the unstable components in the magnetic field of the bend pipes.

Thermal magnetic cleaning of the unstable magnetic components, involving heating or low-temperature treatment.

Chemical magnetic cleaning, which chemically treats the unstable magnetic components.

Since there can be numerous factors contributing to the instability of the magnetic field, which may affect the use of bend pipes, it is essential to clear any excess magnetism from the pipes to prevent adverse situations from occurring again.

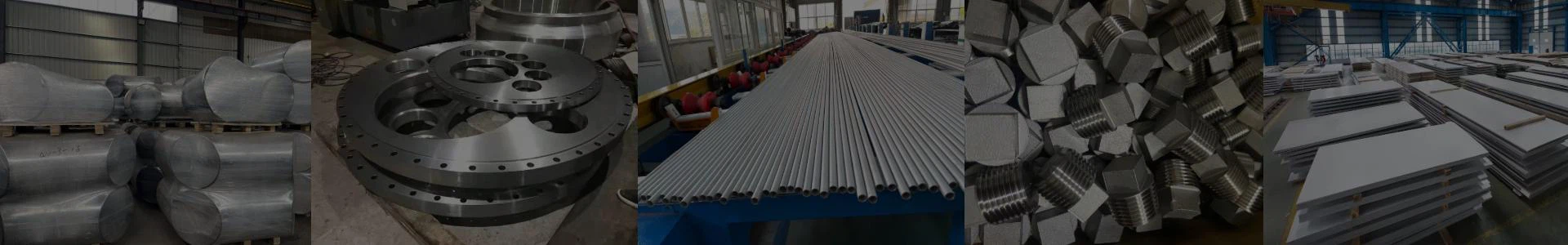

SINO SPECIAL METAL is a trusted supplier of pipes, flanges, and fittings. Feel free to inquire and make purchases.