ASME B18.2.2 Hex Nut

Common Types:

Regular Hex Nut: Also known as a finished hex nut, it has six flat sides and is the most commonly used type.

Heavy Hex Nut: Similar to the regular hex nut but with thicker walls and a larger bearing surface, providing increased strength and load-bearing capacity.

Nylon Insert Lock Nut: Features a nylon insert that provides resistance to loosening caused by vibration or torque.

Flange Nut: Includes a built-in washer-like flange at one end, providing a larger bearing surface and reducing the risk of embedding into softer materials.

Common Sizes:

Hex nuts come in various sizes, typically specified by the thread size and pitch, with common measurements including M6, M8, M10, M12, etc.

Common Materials:

Common materials for hex nuts include:

Carbon Steel: Suitable for general applications.

Stainless Steel: Offers corrosion resistance, ideal for outdoor or corrosive environments.

Brass: Provides good corrosion resistance and electrical conductivity, commonly used in electrical and plumbing applications.

Manufacturing Process:

The manufacturing process of hex nuts involves:

Cold Forming: Forming raw material blanks into the desired hex shape using cold heading machines.

Machining: Trimming excess material and forming threads using machining equipment.

Surface Treatment: Includes processes like plating, coating, or passivation for corrosion resistance and aesthetics.

Quality Control:

Raw Material Inspection: Ensuring materials meet specifications and standards.

Dimensional Inspection: Checking dimensions such as width, height, and thread accuracy.

Thread Inspection: Verifying thread quality and pitch conformity.

Torque Testing: Testing the resistance to loosening under specified torque conditions.

Procurement and Usage Points:

Select hex nuts with the appropriate material, size, and specifications for the intended application.

Ensure proper thread engagement and torque when installing nuts to prevent over-tightening or loosening.

Use washers under nuts to distribute load and prevent surface damage.

Common Problem Analysis:

Thread Misalignment: Could result from manufacturing defects or improper machining, leading to difficulty in nut installation.

Thread Galling: Occurs due to friction during installation, causing threads to seize or gall.

Over-Tightening: May lead to stripping of threads or deformation of the nut, compromising its integrity and effectiveness.

By following proper procurement and usage guidelines and implementing rigorous quality control measures, common issues with hex nuts can be mitigated, ensuring their reliability and performance in various applications.

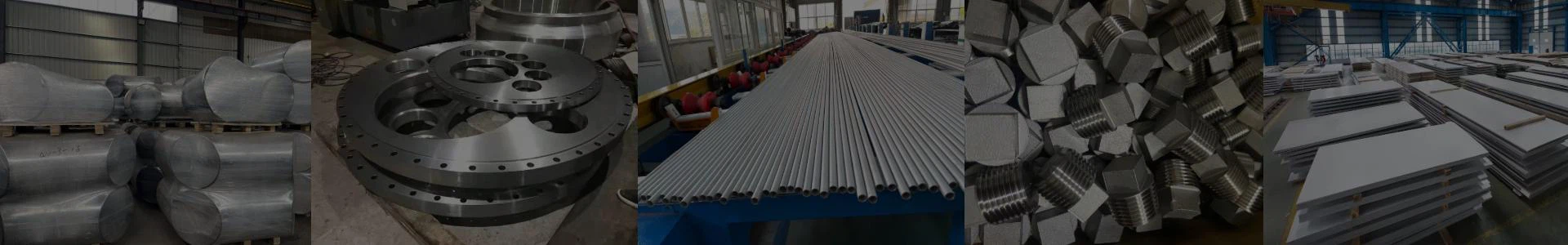

Hot Tags: asme b18.2.2 hex nut, China asme b18.2.2 hex nut manufacturers, suppliers, factory, titanium tube fittings, hastelloy c276 tube, Nickel Alloy Pipe Fittings, c276 flanges, carbon steel anchor bolt, super duplex 2507 fasteners

Previous

Stainless Steel FastenersNext

No InformationYou Might Also Like

Send Inquiry