Austenitic Stainless Steel Flange

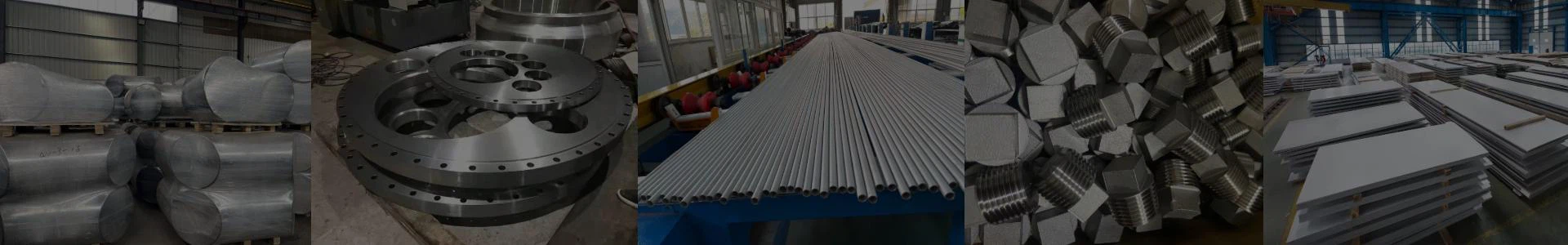

High-Performance Austenitic Stainless Steel Flanges for Demanding Industries

SSM specializes in manufacturing austenitic stainless steel flanges from grades 304, 316, and 316L. Our flanges offer exceptional corrosion resistance, high strength, and excellent formability, making them ideal for chemical processing, oil & gas, marine, and food processing applications.

Austenitic Stainless Steel Flange Specifications

1. Standard Dimensions & Pressure Ratings

| Type | Size Range | Pressure Ratings | Standards |

|---|---|---|---|

| Slip-On (SO) | 1/2" - 60" (DN15 - DN1500) | Class 150 - 2500 (PN6 - PN100) | ASME B16.5, EN 1092-1 |

| Weld Neck (WN) | 1/2" - 60" (DN15 - DN1500) | Class 150 - 2500 (PN6 - PN100) | ASME B16.5, EN 1092-1 |

| Blind (BL) | 1/2" - 60" (DN15 - DN1500) | Class 150 - 2500 (PN6 - PN100) | ASME B16.5, EN 1092-1 |

| Threaded (TH) | 1/2" - 24" (DN15 - DN600) | Class 150 - 900 (PN6 - PN40) | ASME B16.5, BS 4504 |

| Socket Weld (SW) | 1/2" - 4" (DN15 - DN100) | Class 150 - 600 (PN6 - PN25) | ASME B16.5, BS 4504 |

2. Material Properties & Characteristics

| Property | 304 (1.4301) | 316 (1.4401) | 316L (1.4404) |

|---|---|---|---|

| Structure | Austenitic | Austenitic | Austenitic |

| Yield Strength (MPa) | 205 | 205 | 170 |

| Tensile Strength (MPa) | 515 | 515 | 485 |

| Elongation (%) | 40 | 40 | 40 |

| Hardness (HB) | 201 | 217 | 217 |

| Magnetic Permeability | <1.02 | <1.02 | <1.02 |

3. Corrosion Resistance Comparison

| Environment | 304 Performance | 316 Performance | 316L Performance |

|---|---|---|---|

| General Corrosion | Excellent | Excellent | Excellent |

| Pitting Resistance | Good | Excellent | Superior |

| Crevice Corrosion | Fair | Good | Excellent |

| Stress Corrosion Cracking | Fair | Good | Excellent |

| Chloride Resistance | Limited | Good | Superior |

Key Advantages of SSM Austenitic Stainless Steel Flanges

✔ Superior Metallurgical Stability - Maintains properties at high temperatures (up to 800°C)

✔ Excellent Weldability - Low carbon content prevents carbide precipitation

✔ Non-Magnetic Properties - Ideal for sensitive electronic environments

✔ Cryogenic Toughness - Performs well in extreme low temperatures (-196°C)

✔ Hygienic Surface - Easy to clean and sterilize for food/pharma applications

Special Features & Custom Options

Enhanced Surface Finishes:

#4 Brushed Finish

Mirror Polish (Ra ≤ 0.4μm)

Electropolished (for ultra-clean surfaces)

Special Configurations:

RTJ (Ring Type Joint) faces for high-pressure applications

Tongue-and-groove faces for precise alignment

Custom bolt hole patterns

Testing & Certification:

100% PMI (Positive Material Identification)

IGC (Intergranular Corrosion) testing

Ferrite content verification

Third-party inspection available

Industry Applications

Chemical Processing:

Acid storage tanks

Reactor vessels

Chemical transport pipelines

Oil & Gas:

Offshore platforms

Refinery piping

LNG terminals

Food & Beverage:

Brewery equipment

Dairy processing

Pharmaceutical piping

Marine & Coastal:

Seawater desalination

Shipbuilding

Coastal power plants

Why Choose SSM for Austenitic Stainless Steel Flanges?

• In-House Metallurgical Lab for quality assurance

• Advanced CNC Machining for precision tolerances

• Complete Traceability from raw material to finished product

• Global Certifications: PED 2014/68/EU, ASME, API, ISO 9001:2015

• Just-in-Time Manufacturing for urgent requirements

Request Your Custom Quote Today

SSM provides competitive pricing and fast delivery for all austenitic stainless steel flange requirements. Our engineering team can assist with:

Material selection guidance

CAD modeling

Pressure rating calculations

Application-specific recommendations

Hot Tags: austenitic stainless steel flange, China austenitic stainless steel flange manufacturers, suppliers, factory, threaded flange, Incoloy Flanges, nickel 201 flanges, cuni flange, Titanium Flanges, incoloy 825 flanges

You Might Also Like

Send Inquiry