ASTM A376: The Standard for Seamless Austenitic Steel Pipe for High-Temperature Service

Introduction: ASTM A376 is a widely recognized standard that sets guidelines for seamless austenitic steel pipes used in high-temperature service. This article provides an overview of ASTM A376, highlighting its key features, applications, and benefits in the context of high-temperature environments.

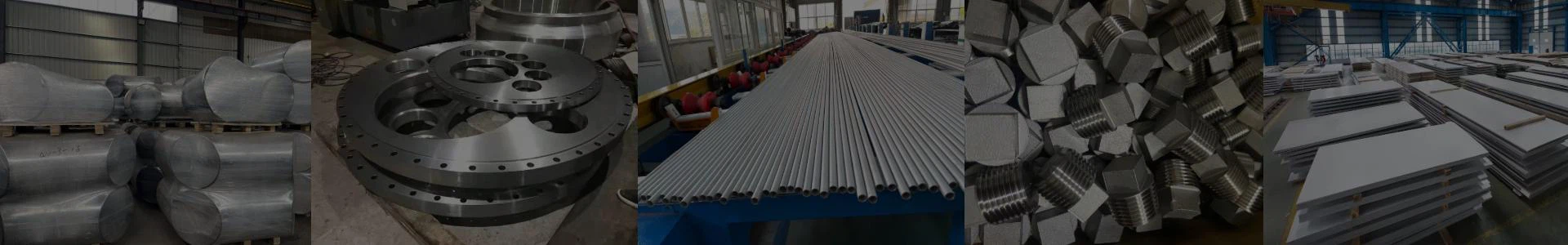

Understanding ASTM A376: ASTM A376 is a specification that specifically addresses seamless austenitic steel pipes used in high-temperature applications. The standard covers several grades of pipes, which are designed to provide reliable performance, high-temperature strength, and resistance to oxidation and corrosion.

Key Features and Benefits: ASTM A376 offers several advantages that make it suitable for high-temperature service:

High-temperature strength: The austenitic stainless steels specified in ASTM A376 exhibit excellent strength and resistance to deformation at elevated temperatures, making them ideal for high-temperature applications.

Resistance to oxidation and corrosion: ASTM A376 pipes are designed to withstand the harsh conditions of high-temperature environments, including oxidation and corrosion, ensuring their long-term durability and reliability.

Seamless construction: ASTM A376 pipes are manufactured using seamless processes, ensuring superior quality, dimensional accuracy, and the absence of welded joints that can be prone to failure under high-temperature conditions.

Versatility in applications: The standard covers various stainless steel grades, including TP304, TP316, TP321, and more, allowing for customization based on specific high-temperature requirements.

Compatibility with other materials: ASTM A376 pipes can be easily integrated with other piping materials, such as fittings and flanges, enhancing their versatility and applicability in complex systems.

Application Areas: ASTM A376 pipes find extensive application in industries that require reliable performance in high-temperature environments, including:

Power generation: ASTM A376 pipes are commonly used in power plants, including thermal power stations and nuclear power plants, for applications such as boiler tubes, superheaters, and heat exchangers.

Petrochemical industry: These pipes find usage in refineries and petrochemical plants for high-temperature processes, including hydrocarbon processing, steam cracking, and chemical production.

Oil and gas industry: ASTM A376 pipes are employed in high-temperature applications such as steam injection and steam-assisted gravity drainage (SAGD) systems used in oil extraction processes.

Heat exchangers and condensers: They are utilized in various heat transfer equipment, including heat exchangers and condensers, where high-temperature fluids are involved.

Aerospace industry: ASTM A376 pipes are used in aerospace applications that require high-temperature resistance and strength, such as jet engines and aircraft exhaust systems.

Comparisons and Alternatives: While ASTM A376 is widely utilized, alternative standards and materials may be suitable for specific high-temperature applications. Some options include:

ASTM A312: This standard covers seamless and welded austenitic stainless steel pipes for general corrosive and high-temperature service.

ASTM A213: It focuses on seamless ferritic and austenitic alloy-steel tubes for high-temperature applications, such as boilers and heat exchangers.

Nickel-based alloys: In certain high-temperature applications requiring superior corrosion resistance and thermal stability, nickel-based alloys may be preferred.

Conclusion: ASTM A376 serves as a reliable standard for seamless austenitic steel pipes used in high-temperature service, offering high-temperature strength, oxidation and corrosion resistance, and versatility in applications. Its application spans across various industries, including power generation, petrochemical, oil and gas, aerospace, and heat transfer equipment. Understanding the features, applications, and benefits of ASTM A376 enables industries to make informed decisions when selecting pipes for their specific high-temperature requirements.